When it comes to vacuum packing, one of the most frequent questions relates to which vacuum bag to choose. How do I know what each type of vacuum bag used should be for? In this post we are going to talk about the different types of vacuum bag and explain what each of them is used for.

The importance of choosing the right vacuum bag

As our corporate chef Enrique Fleischmann, an expert in vacuum and low-temperature cooking, explains, the first thing to understand is that not all vacuum bags can be used for everything. That is why you have to know how to pick a vacuum bag that is going to work with the elements you are using. In addition, you need to consider that, even if you are not a specialist in plastics, the company that supplies the bags will have done all the necessary tests and should be able to provide a technical sheet with all the information. It is important to think about acidity, salinity, freezing temperature, exposure temperature and time, etc. so that above all we understand that a plastic bag, if subjected to heat or cold, could end up migrating to the food. This means that the bag, at a given moment, could lose its original characteristics with the danger that these migrations could stick to the packaged food.

Types of vacuum bag

We have different vacuum bags that vary in terms of the thickness of the bag and the proportion of polyamide and polyethylene.

- Conservation bags: these are vacuum bags in which conservation is vital. They are ideal for packaging and storing both fresh and cooked products. Most of them can also be used for pasteurisations, or in other words, for cooking up to 80 degrees.

However, not all of them are suitable for cooking at more than 80ºC or for freezing. It is important to check whether the bags can be used for cooking and/or freezing since if the temperature is exceeded it could result in the plastic degrading. Normally, bags for cooking and freezing are very similar to conservation bags, but they are normally firmer and thicker. These are normally suitable for cooking up to 120ºC and for freezing down to -21ºC. For cooking at temperatures above 120ºC you will need to use metallic bags, which are discussed later.

- Shrink bags: shrink bags can be used to retain the shape of the packaged product. While they appear to be very thin bags, when they are subjected to heat they contract and become very hard, “sticking” to the product more. They are particularly suitable when you want to emphasise the shape of the product, such as with a leg of ham, and they are also particularly suitable for conserving juices within the bag. They are used above all for meat and cheese products.

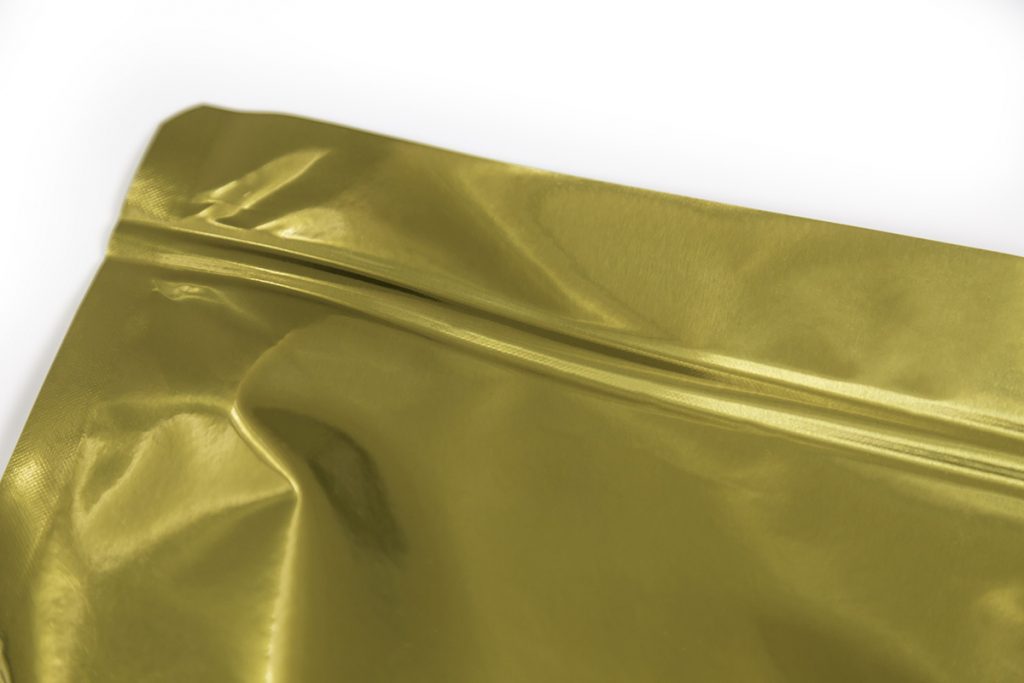

- Metallic bags: metallic bags a relaminated vacuum bags that can withstand a large amount of pressure and better retain the characteristics of the packaged product. In addition, since no light can enter the bag, the products do not lose their organoleptic quality to the eye. These bags are normally used in the food industry. There are two types of metallic bag, one where both parts are metallic and a second where the back is metallic and the front is plastic. These are normally used to make the product look more attractive. For example, with packaged cold meats. Metallic bags are used when cooking at more than 120ºC, since they are thicker and their structure is fully resistant to pressure without losing its original qualities.

Important: not all vacuum packing machines can seal this type of bag. Check that your machine can work with these bags. For example, we have Sensor Ultra vacuum packing machine models that can seal these bags.

- Compostable bags: increasing numbers of suppliers are trying to find a solution to the problem of the use of plastic. Although all the other bags mentioned in this report can be recycled, they rely on people doing this. Compostable bags go one step further and do not use plastic in their composition. However, these bags do not handle temperatures very well since there is degradation at both high and low temperatures. Nor are they very good with humidity. That is why they are not suitable for freezing and they only allow for cooking up to temperatures of 85ºC for twelve hours at most. They are a very good option for conserving fresh products and/or dishes that do not need to be heated or regenerated.

Important: many suppliers are working in this area and there are biodegradable bags that can be used at other temperatures and for different exposure times.

Other packaging options

- Heat-sealed trays: there are two types of heat-sealed tray. First, the most common are the trays into which the cooked product is placed before being heat-sealed, but there is no vacuum inside. Second, there are trays with a vacuum inside that need more sophisticated machinery, which does the same process as before but halfway through a chamber generates a vacuum and then directly covers it with plastic.

Important: remember that trays are not normally a very good option for vacuum cooking since they tend to float.

- Glass jars: these are a very good option for conserving and/or flavouring products. More information here.